A hybrid printer is built for a very specific buyer: a screen print shop or garment factory that already runs volume, but wants digital capability (detail, personalization, rapid artwork changes) without giving up the speed and economics of screens.

Done right, hybrid isn’t “DTG added to screen printing.” It’s a production strategy: use screen where it’s unbeatable, use digital where it adds margin and flexibility, and run both through a workflow that stays stable at factory pace.

If you’re comparing real production options, start here for an overview of Textalk hybrid direction and why factories adopt it:

https://fluxmall.com/en/textalk-hybrid-printers-integrate-screen-printing-dtg-for-mass-production/

Hybrid printer: What it is (and what it isn’t)

A hybrid printer is a garment printing system that combines screen printing and direct-to-garment digital printing in one integrated workflow – so you can choose the best method per design element (or per order type) while keeping production continuous.

It’s not the same as “Having both a DTG printer and a screen press” in separate corners of the shop with separate workflows.

A true hybrid approach is “Screen underbase + DTG on top” and about process repeatability: predictable color and placement, consistent curing/finishing, stable throughput across shifts, reduced changeover pain when orders vary.

Screen printing + DTG hybrid: How it combines screen and digital in production

A screen printing + DTG hybrid workflow usually follows one of these patterns, depending on your product mix and bottlenecks:

Pattern A: Screen for bases, digital for complexity

Screen printing handles what it’s best at:

- Large solid areas

- Spot colors

- Underbases for dark garments (where stable coverage matters)

DTG then adds what screen struggles with at speed:

- Photographic detail

- Gradients

- Multicolor art without extra screens

- Personalization elements (names, numbers, variants)

This pattern is common when you run high volume but want to expand into more complex designs without slowing the press with extra screens and registrations.

Pattern B: Screen for volume winners, DTG for variability

You keep screen printing for:

- Repeat designs

- Bulk runs

- Lower cost per unit at scale

You route DTG for:

- Short runs

- Ecommerce variability

- Fast design refreshes

- “Test-and-repeat” programs where only winners become screen runs

That’s how many shops increase revenue without forcing every order through the same method.

Pattern C: Hybrid line built for continuous flow

In factory contexts, hybrid printer becomes a line decision: how garments move, how curing is managed, and how jobs are sequenced to keep stations fed. That’s when “hybrid” stops being a capability and becomes a production system.

For a concrete example of hybrid production positioning with Textalk systems, you can explore the Textalk collection here:

https://fluxmall.com/en/product-tag/textalk/

Hybrid printing system: Where it fits vs pure screen printing and pure DTG

A hybrid printing system makes the most sense when your business has both of these realities:

- You need screen-level throughput for profitable volume

- You’re losing opportunities because you can’t profitably produce high-mix, high-detail, or personalized work

Here’s a practical comparison that production buyers tend to agree with:

| Decision factor | Pure screen printing | Pure DTG | Hybrid DTG system |

|---|---|---|---|

| Best at | Large repeats, low unit cost at volume | Short runs, complex art, frequent changes | Volume + complexity without forcing one method |

| Changeover pain | Higher (screens, setup, cleanup) | Low (file-to-print) | Lower than screen for complex jobs (digital carries detail) |

| Detail/gradients | Possible but slower/more setup | Excellent | Excellent (digital handles complexity) |

| Personalization | Inefficient | Strong | Strong (digital handles variants while screen runs bases) |

| Scaling output | Great when designs repeat | Requires tight maintenance and workflow | Strong when line is engineered for stability |

If your current business is “mostly repeats,” pure screen may remain the best core. If your orders are “mostly one-offs,” pure DTG can be enough. Hybrid is for shops living in the middle: volume plus variability.

Digital + screen integration: What the production workflow looks like

Digital + screen integration succeeds or fails on workflow design, not on marketing claims. In industrial environments, the key is to avoid creating a “hybrid bottleneck” where one station starves the others.

A stable hybrid workflow usually includes:

Job routing rules (so operators don’t guess)

Hybrid shops win when they standardize routing:

- Which designs go screen-only?

- Which go digital-only?

- Which are hybrid?

This is often decided by:

- Number of colors/ complexity

- Run length

- Garment color (dark vs light)

- Delivery time

- Margin target

Pretreat and curing plan (because both methods must finish reliably)

In hybrid, finishing becomes shared infrastructure:

- Curing capacity must match peak output

- You need consistent rules for wash durability and hand feel

- You must avoid over-curing or under-curing when jobs are mixed

If you’re designing around industrial stability (not just capability), the scaling logic is similar to how factories think about production DTG lines – this industrial scaling article explains the “line first” mindset clearly:

https://fluxmall.com/en/how-hybrid-dtg-printer-help-you-scale-apparel-printing-textalk-printers/

Quality control checkpoints that protect throughput

Hybrid printer increases capability, but it also increases variation if QC is weak. A practical approach is:

- Quick visual QC on every piece (placement + obvious defects)

- Periodic wash/adhesion checks per job type

- Clear reprint rules (when to re-run screen, when to re-run digital)

Hybrid garment printing: Typical applications that justify hybrid

Hybrid garment printing is most valuable when it unlocks revenue you can’t capture efficiently with one method alone.

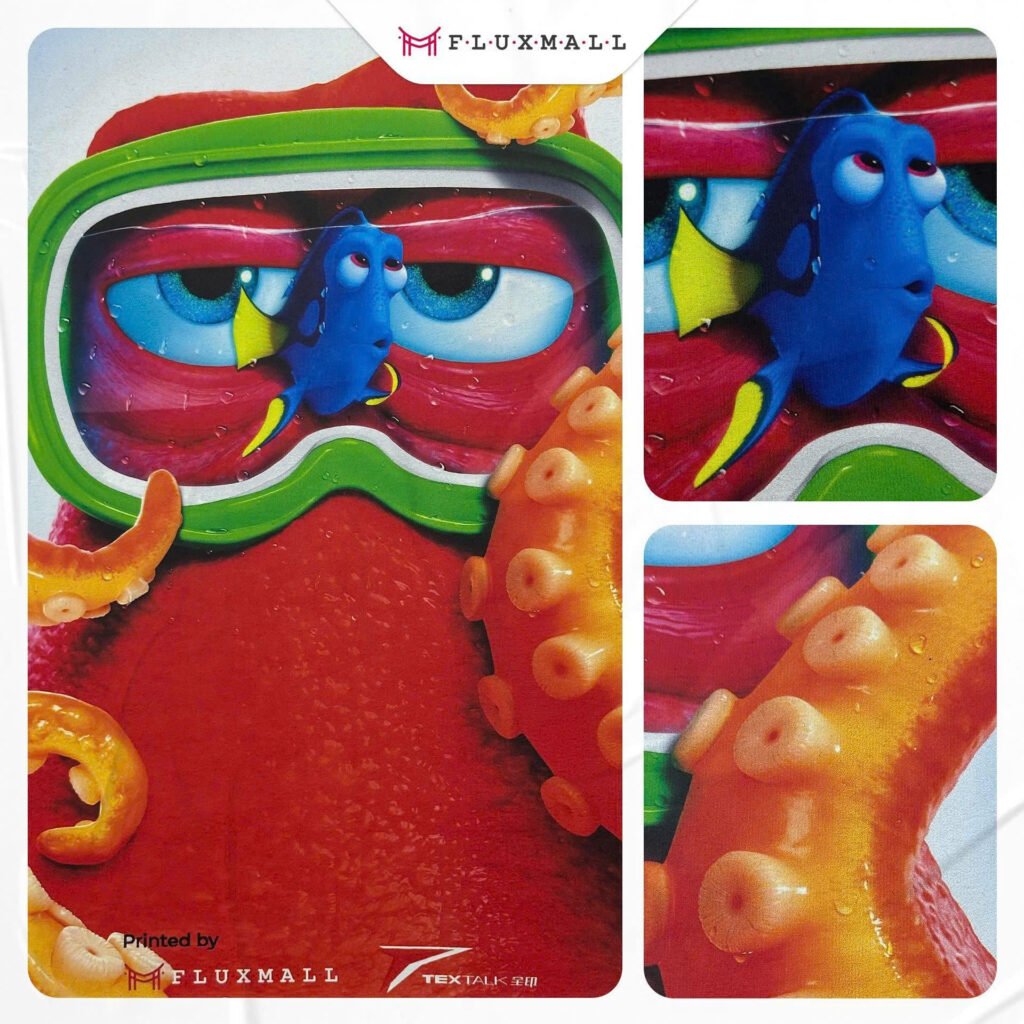

1) Licensed and retail graphics with high-detail elements

Screen can lay down bold bases and spot colors, while DTG adds the fine detail and gradients that would otherwise require extra screens and slower setups.

2) Teamwear, events, and personalization at volume

Hybrid is a strong fit when you need: consistent bulk output (screen advantage) and personalization or variant SKUs (digital advantage)

3) “Test-and-scale” product programs

Many brands test dozens of designs in small runs. Hybrid lets you: start digitally (fast feedback, low setup), graduate winners into screen runs (lower unit cost at volume), keep long-tail variants digital without disrupting production

4) Factory programs with mixed order profiles

Factories often have a blend of:

- predictable bulk orders

- seasonal spikes

- urgent reorders

- customer-specific variants

Hybrid helps absorb variability without forcing the whole line to slow down.

If you’re evaluating systems for factory-style deployment rather than a small-shop add-on, Textalk’s hybrid production direction is worth reviewing:

https://fluxmall.com/en/textalk-hybrid-printers-integrate-screen-printing-dtg-for-mass-production/

Hybrid printer: What to evaluate before you upgrade

A hybrid printer purchase should be evaluated like a production change, not a printer purchase. These are the criteria that usually determine success in real operations:

Throughput you can finish (not just print)

Your KPI should be: finished, shippable garments per shift.

Ask vendors to define throughput including:

- loading/unloading rhythm

- curing time and capacity

- changeover rules between job types

Uptime and maintenance reality

Hybrid is a long-run game. If the digital side is unstable, it becomes the reason the line stops. Your evaluation should include:

- daily maintenance routine time

- failure modes that stop production

- service model and parts readiness

Integration with existing screen workflow

The biggest hidden cost is disruption. A good hybrid path:

- fits your press rhythm

- minimizes operator confusion

- standardizes job routing

- avoids rework spikes

Scalability path (how you grow output)

Ask: “What happens when we add a second line or increase shifts?”

Hybrid should scale by design:

- modular capacity growth

- consistent training and SOPs

- predictable finishing expansion

If you want to explore Textalk models and formats aligned with hybrid scaling, the TKR series overview is a helpful starting point:

https://fluxmall.com/en/textalk-tkr-series-overview/

Hybrid printing system FAQ

What’s the simplest way to start hybrid?

Many shops start by routing: repeat bulk designs to screen, complex art and personalization to DTG, then they add hybrid routing rules once the workflow is stable.

Does hybrid replace screen printing?

No—hybrid is usually adopted to protect screen printing as the volume engine while adding digital capability where it increases margin or reduces setup pain.

When is pure DTG better than hybrid?

If most of your orders are short-run and highly variable, and you don’t rely on high-volume repeat work, pure DTG can be simpler.

What should I ask in a hybrid demo?

Ask to see:

- a real production sequence (not only one print)

- job routing logic for different order types

- finishing and curing plan for mixed workflows

- uptime expectations and daily maintenance routine

If you’re ready to compare a production-ready hybrid direction with Textalk, you can book a demo here:

https://fluxmall.com/en/appointments/book-demo-textalk-printer/